Application Brief

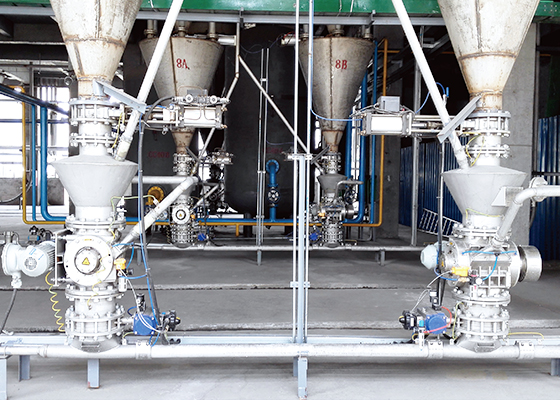

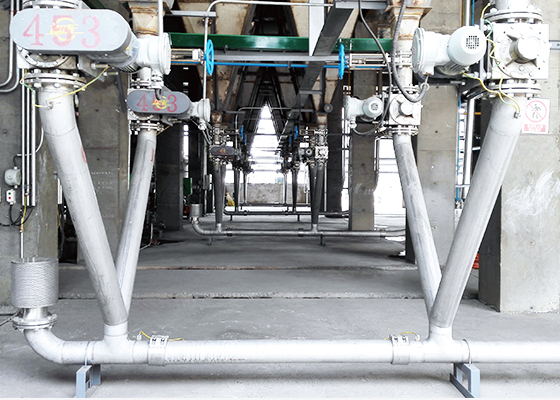

Pneumatic conveying is a technology that transfers solid material from one or several locations to other locations in pipe by use of air flow (normally air). After decades of year’s development, Sino-Auto has developed a complete package of pneumatic conveying technology which is successfully used in industrial field of chemical, food, pharmaceutical and battery.

TEL:+86 20 83553890

TEL:+86 20 83553890